The recycled plastic flakes are amorphous, when heated to its glass-transition temperature it will begin to soften, stick together, and bridge, causing material flow interruptions in the drying hopper. A hot-air dryer is designed for drying virgin plastic pellets, which are in crystal state.

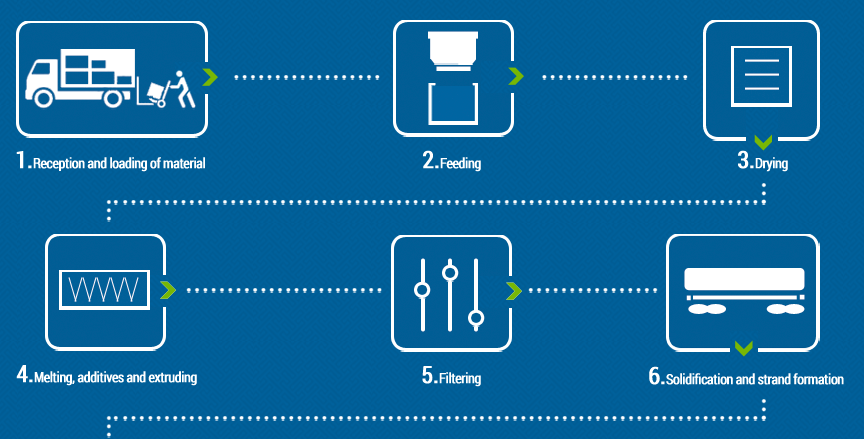

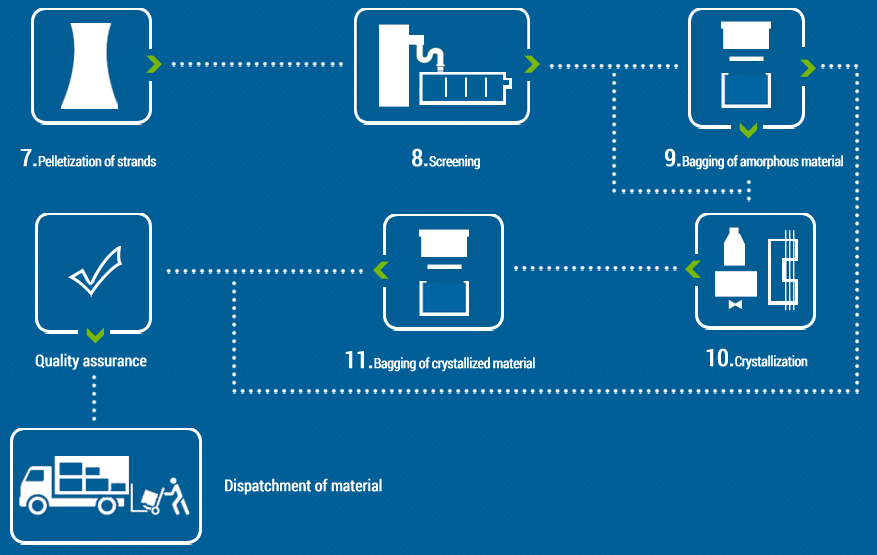

Even the recycled plastic pellets are crystallized. The following is the process of PET recycling. The last process before dispatch is capitalization.

Recycled plastic flakes cannot be completely dried with a general dryer which uses hot air only.

A crystallizer transforms the amorphous plastic material into crystal state and drys the material completely.

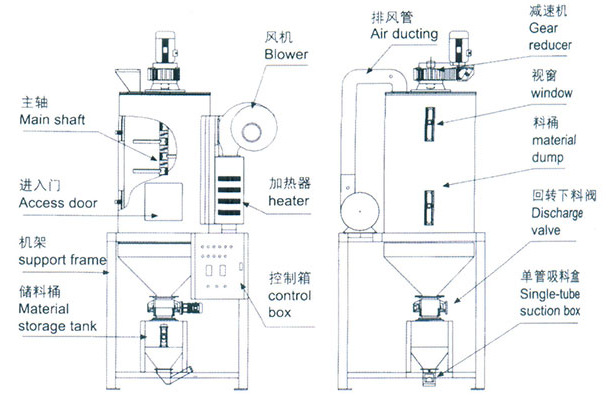

It’s designed for PET processing.

This machine is a perfect mixing drying for other kinds of plastic material as it mixes in slow speed while drying at a high temperature up to 180 centigrade.